Rodillo de doble capa que forma la máquina

Información básica

Modelo: WLDL

Descripción del producto

Rodillo de hoja de techo de doble capa que forma la máquina

Descripción del producto

La máquina formadora de rollo de láminas de doble capa WLDL consta de desenrollador y su base, guías de alimentación, estaciones de formación de posición fija,

Dispositivo de corte, estación hidráulica, consola de control de PLC y así on.Our empresa tiene cientos de modelos de perfil para esta serie

Rodillo que forma la máquina, tal como WLDL66-77, WLDL50-375, WLDL18-76, y el etc.

Podemos diseñar la máquina como su muestra o perfil

Principales parámetros técnicos:

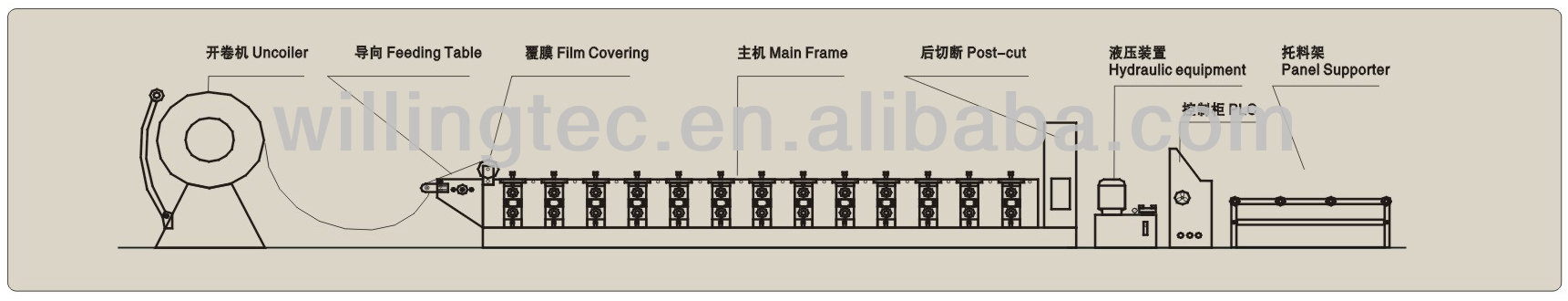

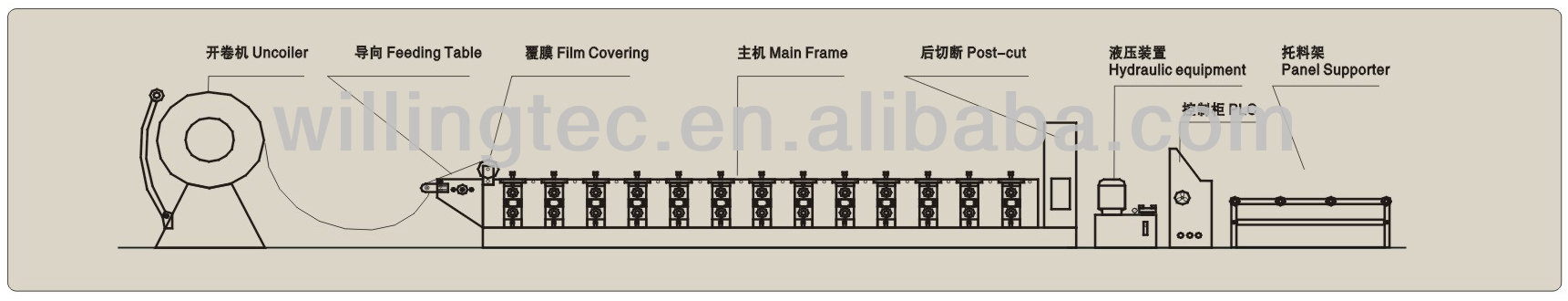

Flujo de trabajo:

Desencolar la hoja ------ Guiado de la hoja ------ Enrollar el molde ------ Presionar el panel ------ Medir la longitud ------ Cortar el panel ----- -Paneles al partidario

Equipo estándar de la máquina:

Componente y Función:

Dibujos del perfil:

Material del equipo principal:

Embalaje y envío Cuerpo principal del nake de la máquina cargado en el envase, cubierto con la película plástica, piezas de repuesto en caja de madera.

Nuestros servicios

Información de la empresa Nuestra empresa, Zhejiang Willing International Co., Ltd es un proveedor profesional en el campo de la construcción de estructuras de acero, especialmente bueno en la fabricación de la máquina.

presentacion de producto

Descripción del producto

La máquina formadora de rollo de láminas de doble capa WLDL consta de desenrollador y su base, guías de alimentación, estaciones de formación de posición fija,

Dispositivo de corte, estación hidráulica, consola de control de PLC y así on.Our empresa tiene cientos de modelos de perfil para esta serie

Rodillo que forma la máquina, tal como WLDL66-77, WLDL50-375, WLDL18-76, y el etc.

Podemos diseñar la máquina como su muestra o perfil

Principales parámetros técnicos:

| Model | WLDL | |

| Material | Type | Pre-paited steel sheet |

| Thickness | 0.2-0.7 mm | |

| Yield stress | 230-550 Mpa | |

| Max.Forming speed | 8-12 m/min | |

| Roller material | 45#Steel with chrome treatment | |

| Roller driven type | Chain transmission | |

| Controller | PLC | |

| Operation | Touch screen and button | |

| Hydraulic system pressure | 12 Mpa | |

| Hydraulic station motor power | 5.5 KW | |

| Main motor power | 7.5KW | |

| Total power | 13 KW | |

| Total weight | About 10000 Kg | |

| Index error of length | 10m±2mm | |

| Voltage | 380V 3 phase 60Hz or at buyer's requirement | |

Flujo de trabajo:

Desencolar la hoja ------ Guiado de la hoja ------ Enrollar el molde ------ Presionar el panel ------ Medir la longitud ------ Cortar el panel ----- -Paneles al partidario

Equipo estándar de la máquina:

| 5 tons manual un-coiler | 1 |

| Pre-cutting device (manual)-optional | 1 |

| Guiding equipment | 1 |

| Film covring equipment | 1 |

| Roll forming equipment | 1 |

| Pressing equipment | 1 |

| Post-cut equipment | 1 |

| Hdraulic station | 1 |

| PLC control panel | 1 |

| Support tables | 2 |

| Coil Feeding Equipment | Consists of one uncoiler with capacity of 5000kgs and its base. The steel sheet is manually fed to the guiding equipment under the function of friction and traction |

| Guiding Equipment | Adopting guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming equipment. |

| Mainframe Transmission | Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet. |

| Roll forming system | The main frame of machine is welded separately and the outside wall is connected by screw after being rotoblasted on the surface.The rollers are surface-chromeplated after being machined by the exact machine tool. |

| Pressing equipment | After formed the shape of the tile panel, pressing the tile panel with pressing equipment which ensures the shape lasting and more beautiful. |

| Post Cut Equipment | The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. |

| Hydraulic Station | Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power. |

| PLC Control Panel | The electric controlling system of this machine consists of five parts: operating system, screen, PLC, transducer and strong electricity part. The controlling system of this machine are imported from Mitsubishi company of Japan. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be choosed operation by manual or automatically. |

Material del equipo principal:

| Roller Material | High grade No.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm |

Active Shaft Material |

High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. |

| Electric Elements |

PLC control panel, transducer imported from Mitsubishi of Japan. Other elements are from famous suppliers of China. |

| Cutter blades | Cr12 mould steel with quenched treatment. |

| Oil tank | model of hydraulic system:CB-E310 |

Embalaje y envío Cuerpo principal del nake de la máquina cargado en el envase, cubierto con la película plástica, piezas de repuesto en caja de madera.

Nuestros servicios

Información de la empresa Nuestra empresa, Zhejiang Willing International Co., Ltd es un proveedor profesional en el campo de la construcción de estructuras de acero, especialmente bueno en la fabricación de la máquina.

presentacion de producto

Grupos de Producto : Pared y techo rodillo que forma la máquina

Premium Related Products

Otros productos

Productos hot

Máquina formadora de rollo de aluminioRodillo de acero de alta resistencia de la plataforma que forma la máquinaTornillo autoperforado del taladro de la cabeza del taladro con el fabricante de goma del fabricantePanel sándwich de espuma EPSPanel de techo de acero inoxidable laminado en frío galvalume / PPGL de acero laminado en fríoMáquina de doblar prensa hidráulicaLongitud de medición de la máquina de corteUncoiler hidráulico de acero de los fabricantes chinosMading en China Bobina de acero laminado en frío Máquina de corte simpleMáquina de grabado personalizadaAcero C purlins rodillo de acero que forma la máquinaAcero y PPGI embossding la máquinaPPGI esmaltado azulejos rollo que forma la máquina WILLING CompanyConstrucción de la máquina de laminado en fríoHoja trapezoidal panel de pared de azulejos roll forming machine hot in indianPerfil de acero Perfil de la máquina